Tyre recycler Green Distillation Technologies has made a new application for a Queensland Government Resource Recovery grant to help built a processing plant in Toowoomba.

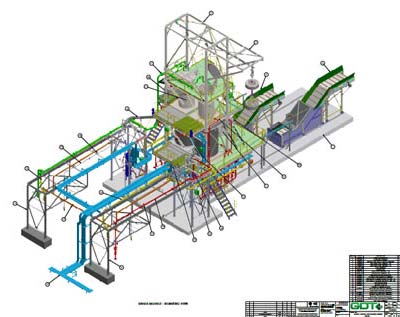

They were unsuccessful with a previous application for $5 million, which is half of the estimated capital cost of building the facility which will process 19,300 tonnes, or a mix of about 700,000 car and truck tyres per year, to yield approximately 8 million litres of oil, 7,700 tonnes of carbon and 2,000 tonnes of steel. The oil will go to Gladstone for refining into fuel.

Trevor Bayley, the Chief Operating Officer of GDT said that the Government did not allocate all the $100 million that was made available for the grants last year and we have been assured that some misunderstandings from our last application have now been clarified in the new application.

“Our proposed Toowoomba facility will be our first commercial plant and with a projected estimate of more than one million old tyres in the area there will be plenty of raw material to sustain the tyre recycling at full production.

“In fact, we have been told that we are an essential piece in the jigsaw in the creation of Toowoomba as a future transport hub for the entire region, which is one of the fastest growing in Australia.

“There is no market research that tells us exactly how many old tyres there are in the region but our estimates are based on the fact that there are more than four million vehicles registered in Southern and South Eastern Queensland and we know that on average each vehicle requires at least one new tyre each year,” Trevor said.

He said that currently old tyres from the Toowoomba area are sent to Brisbane for recycling which is mainly by cutting the tyres into pieces and sending them to landfill or grinding them into crumbs, but both methods don’t change the composition of the tyre and it will remain a piece of vulcanised rubber for 500 years.

“Our proposed plant in Toowoomba is expected to cost $10 million to construct and will employ 15 to 18 full time staff and more during the construction phase as well as the contractors.

“The GDT process is in line with today’s environmental expectations of a circular economy and the volume of valuable recyclable material produced is impressive with a typical 10 kg car tyre yielding 4 litres of oil, 4kg of carbon, 2kg of steel, a 70kg truck tyre will provide 27 litres of oil, 28 kg of carbon, 15 kg of steel and 4 tonne oversize mining dump truck tyre 1.6 tonnes of carbon, 0.8 tonne of steel and 1500 litres of oil.

“We have set an old tyre collection area of a three-hour truck radius from Toowoomba, which will take us to the Gold Coast, the New South Wales border, west to Chinchilla and include Brisbane, Ipswich, Roma and Kingaroy and provide more full time employment.

“We have discussed setting up a tyre collection transport service with Ability Enterprises of Toowoomba, which is a not-for-profit social enterprise business established to give people a second chance through employment and they are excited at the prospect.

“As well as the estimate of end-of-life-car tyres in the three-hour Toowoomba catchment area there is also the potential for significant numbers of old truck tyres, which of course when processed yield much greater amounts of oil, carbon and steel.

Already there are two very large livestock carriers that call Warwick home, but provide a national service. The future plans for the inland rail and the creation of a $50 million transport hub are also potentially beneficial to the business,” Trevor said.

Released for Green Distillation Technologies by Dennis Rutzou Public Relations (www.drpr.com.au)

For further information please call or Dennis Rutzou on 0411 10 888