GDT Chief Operating Officer Trevor Bayley was a speaker at the 2019 Waste Expo, which was held in Melbourne in late October.

This year the event attracted record crowds, which is a reflection of the increasing public interest in waste and recycling and promises a great future for a company like Green Distillation Technologies which has world first technology that recycles old tyres into valuable oil, carbon and steel.

Trevor opened his address by outlining the extent of the problem with one and a half billion end-of-life tyres being generated around the world each year.

Australia alone contributes 25 million and the US 250 million.

And the world will generate similar quantities of old tyres next year and the year after.

In fact, India has embraced the automotive age and annual tyre production of tyres in China has now passed 960 million.

After showing the audience a picture of burning tyres in his PowerPoint presentation, Trevor posed the question:

“What do you see in this picture?

It’s not just about the toxic black smoke or the clean up after the fire. It’s about the complete waste of energy. It is estimated that only 22% of the energy required to get a new tyre on the road is used during its useful life.

“At GDT we can recover approximately 80% of that retained energy in the form of oil and carbon. How much energy is recovered by crumbing? Zero. Is that what recycling and resource recovery is all about?”

Trevor Bayley then turned to the world first technology that GDT has developed which was invented by their Technical Director Denis Randall.

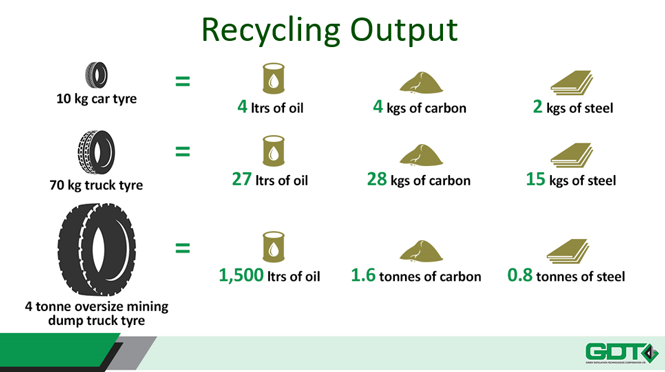

“The volume of valuable recyclable material produced by the process is impressive and a typical 10 kg car tyre will yield 4 litres of oil, 4kg of carbon, 2kg of steel, a 70kg truck tyre will provide 27 litres of oil, 28 kg of carbon, 15 kg of steel and 4 tonne oversize mining dump truck tyre will yield 1.6 tonnes of carbon, 0.8 tonne of steel and 1500 litres of oil.

“The first Australian Green Distillation Technologies processing plant is located 5 kilometres north of Warren in Western New South Wales, which is North West of Dubbo on the Oxley Highway, strategically located on the main trunk road transport route between Brisbane and Melbourne.

“We have received all the Governmental approvals for a second plant at Toowoomba and are now at the capital raising stage. It will be located at the Wellcamp Business Park and process 19,300 tonnes, or a mix of 658,000 car and truck tyres per year, to yield approximately 8 million litres of oil, 7,700 tonnes of carbon and 2,000 tonnes of steel.

Up to this stage we have been financially supported by a band of loyal shareholders and Government grants.

GDT plans to eventually establish ten processing plants in Australia.

This is expected to handle about 30% of the 26 million old car and truck tyres we discard each year and the potential for export of the technology is limitless.

We are constantly fielding enquiries from many countries around the world and we have signed an agreement worth up to $50 million for five processing plants in South Afrca, as well as discussing joint venture deals in Japan, United Kingdom, USA. New Zealand the Middle East and South America.

Trevor finished his address on an optimistic note: “Our vision is that our process will become the standard method of disposing old tyres around the world consistent with the principles of the circular economy by turning a valueless end of life product into valuable reusable materials.

“We hope it is a vision that you all share.”