Tyre recycler Green Distillation Technologies, has signed a deal with New Zealand’s CarbonScape to enhance the value of the carbon produced by its process, turning it into high value graphite.

GDT’s world-first tyre recycling process turns end-of-life car, truck and oversize tyres into high value oil, carbon and steel, while CarbonScape, based in Marlborough, New Zealand has developed patented technology turning sawdust and waste biomass into high purity, high value carbon products, including graphite.

The deal between the two innovative companies solves a global problem as one and a half billion end of life tyres are generated every year. While CarbonScape’s work on sawdust continues, it has been discovered that the carbon produced by GDT’s tyre recycling technology is highly compatible with CarbonScape’s own process for producing graphite.

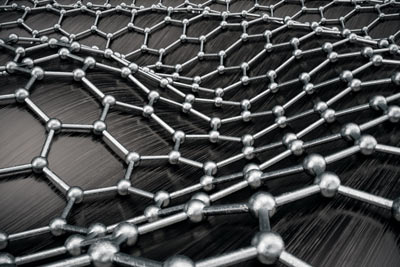

Graphite is a non-metallic mineral and the most stable form of carbon. It is chemically inert, corrosion resistant with a high melting point of 3650°C and is a good conductor of electricity.

China is world’s leading producer of graphite and its reserves are the second-largest worldwide, behind Turkey. However, the industry is under significant environmental pressure due to its mining and purification techniques and CarbonScape presents a sustainable “green” alternative.

Graphite is defined as a ‘critical strategic mineral’ in the USA and Europe and global demand is growing at 5.8% p.a. to 4.2 million tonnes which was worth USD 30 billion to 2018. Within the global graphite market, high purity graphite for Li-ion batteries is forecast to grow at a Compound Annual Growth Rate of 26% to 2029 with pricing estimates of USD5,000 per tonne.

Potential end use of high purity graphite includes Li-ion batteries for use in electric vehicles and stationary storage, solar panels, supercapacitors and other electronic applications.

GDT operate a tyre processing plant at Warren in Western New South Wales, which is where the work on the future co-development of graphite will take place. They are also in the capital fund raising stage for their second commercial plant in Toowoomba, Southern Queensland having secured all the necessary Government approvals.

GDT Chief Operating Officer Trevor Bayley said that the key to operating a successful business in the era of the circular economy is to maximise the return they receive from the materials they produce.

“We have a contract with Southern Oil Refineries to supply their sister company, Northern Oil of Gladstone, with all our oil as it is regarded as light crude and easy to refine into petrol, diesel, jet fuel and other petroleum products and of course the current world price for oil is very high. Our carbon is high quality for use in a variety of products such as printer’s ink, computer cartridges and even cosmetics.

“But by enhancing it to graphite it could sell for multiples of the current price which is a very significant difference.

“Our Technical Director Denis Randall, who developed our process, has long advocated that Resource Recovery is the key to successful recycling and this direction we are taking is consistent with those aims,” he said.

Mr Bayley explained that their recycling process is firmly based on that principle and turns old end-of-life tyres into high value oil, carbon and steel and the processing emissions conform to NSW Environment Protection Agency guidelines.

Released for Green Distillation Technologies by Dennis Rutzou Public Relations (www.drpr.com.au)

For further information please call or Dennis Rutzou on 0411 510 888.