ELT Facts

1 BILLION TYRES

reach their end of life each year

around the world

4.4 BILLION TONNES

end of life tyres generated

in USA annually

350,000 TONNES

end of life tyres in 2018/2019

in Australia

ELT Tyres: The Extent of the Problem

End-of-life (ELT) car and truck tyres have been a blight on the environment ever since they were invented over a century ago. Most people are aware that ELT tyres are a major environmental hazard. But few know the staggering volume that is generated annually.

To get a rough idea of the extent of the problem, a good rule of thumb to go by is that one ELT tyre is generated per person each year. For a country like the United States, that translates to more than 250 million ELTs a year; for Australia, it is over 23 million.

Such tyres often end up as unsightly garbage, dumped in landfills, bushland or waterways. Sometimes they’re even used as furnace fuel. They are also ground into crumbed rubber to make children’s playgrounds, sports courts, public pavements, roads or concrete.

But none of these methods safely or effectively recycle ELT tyres. A more thorough and transformational process is needed – one that completely breaks ELTs down into reusable materials, without harmful emissions.

Why ELT Tyres Are Dangerous

Stockpiled old tyres can become a breeding ground for mosquitoes and a source of dangerous diseases (e.g., dengue fever and Ross River fever).

ELTs are combustible. Once they are ignited, the noxious substances ELTs release can cause significant pollution in the surrounding neighbourhood. Some sites in developed countries like the United States and Australia can even contain as many as 10 million ELTs (e.g., Stawell, Victoria). Should any of these sites catch fire, a large swath of land can become unsafe or uninhabitable for many years.

Burning ELTs “safely” as furnace fuel only creates more greenhouse gases and damaging emissions.

Whether stockpiled, buried or used as crumbed rubber in construction, the chemical makeup of the ELT tyres does not change. Their synthetic rubber typically contains carcinogenic chemicals like polycyclic aromatic hydrocarbons (PAHs), plasticizers, metals, and other volatile compounds. Even when suspended in concrete paving or asphalt, non-biodegradable microparticles from old tyres can still escape through erosion, find their way into the environment and leach out toxic chemicals.

GDT can turn old tyres into oil, carbon and steel – 100% conversion with ZERO harmful emissions

The GDT Tyre Recycling Process

Green Distillation Technologies (GDT) has the solution. Using a technique known as “Destructive Distillation,” GDT can turn ELTs from a wasted resource and environmental hazard to valuable, high-demand raw materials.

Destructive Distillation was developed by the company’s original Chief Technical Officer, the late Denis Randall, after 35 years of study and experimentation into organic waste streams.

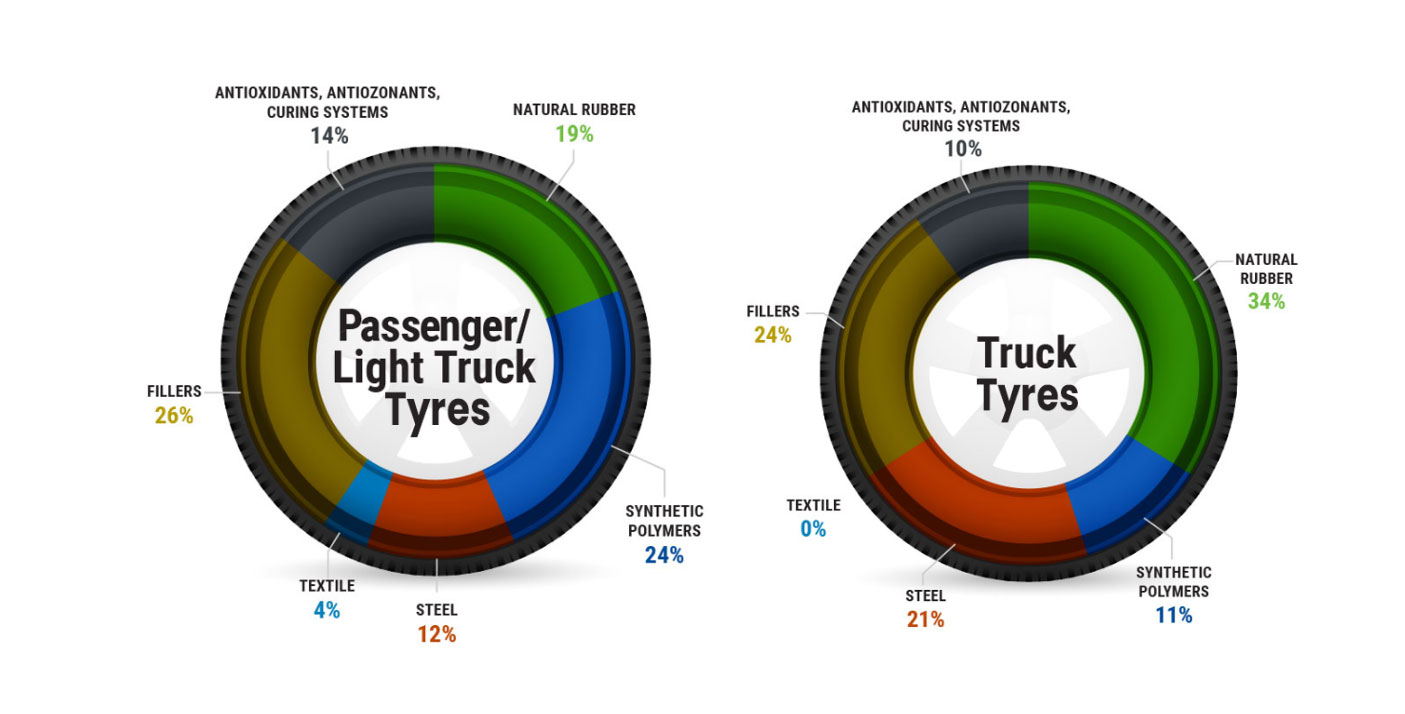

What Typical ELT Tyres Are Made Of

This recycling process transforms any end-of-life car, truck, large-size mining dump or heavy earthmoving equipment tyre into useable quantities of oil, carbon and steel (the same steel reinforcement used in the original tyre-manufacturing process).

Best of all, the process is emission-free.