In the Business of Shrinking

End of Life Tyres

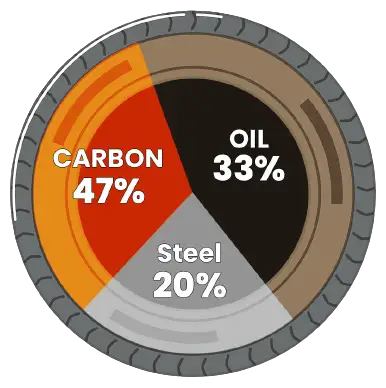

GDT has developed technology that converts tyres back into carbon, oil and steel, without producing emissions.

Currently Operating in New South Wales.

Expanding to Queensland, then to other states in Australia.

Exploring international partnerships.

The GDT Way - Cleanly Transforming End of Life Tyres into Useful Resources.

When The Rubber No Longer Hits The Road!

The GDT – Warren Plant in NSW is receiving tyres for recycling which are processed to produce high value oil, steel and carbon for sale. GDT takes end-of-life tyres (ELT) destined for landfills, or worse, and gives the raw materials new life. We are an active part of the local, national and international solution to this industrial challenge. GDT is now expanding operations to be of greater value to the supply chain as well as delivering on local, state and federal Government tyre waste strategies.

GDT Services

ELT Handling

GDT has competitive tyre disposal rates for commercial clients – GDT uses a technique known as destructive distillation to turn this wasted resource and an environmental hazard into high demand valuable raw materials.

Industrial Oil

The GDT process creates semi-refined oil and this light oil is created from low temperature distillation. GDT uses this oil for fuel at the plant and it is also available to the market for a variety of applications. To find out more, contact us.

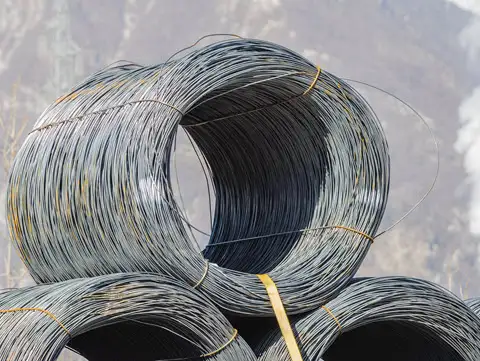

Steel

With a low heat treatment applied during the GDT process, the metal that is sorted after coming off the conveyor belt is ready for steel scrap metal buyers. Like other steel recycling this represents energy saving and is better for the environment compared to the production of virgin iron ore.

Carbon Black

Carbon black is the most widely used industrial chemical in the world. Recovered carbon black (rCB) is sought after worldwide for industrial applications.

Walking The Sustainability and Circular Economy Talk

End-of-life car and truck tyres have been a blight on the environment ever since they were invented over a century ago.

Grinding up old tyres to make crumbs or flakes is not an effective means of recycling tyres as the rubber has not been changed and there is a limit to how much of this material can be used for kindergarten playgrounds and soccer fields. Using it as a furnace fuel in Asia creates noxious greenhouse gases and damaging emissions.

As well as the environmental problems caused by dumps of old tyres or illegally discarding them in bushland and waterways, after rain these tyress become a breeding ground for mosquitoes and a source of dangerous diseases such as Dengue Fever and Ross River Fever.

The task was hard and long but worthy of the time and investment, so the GDT founding group started and completed the journey. From invention to testing then approval and now commercial viability.

News

All pyrolysis isn’t created equal.

By GDT Co-CEO Trevor Bayley A recent BBC investigation into the hazardous processing of millions of tonnes of UK tyre waste in India has highlighted the fact that the world is still grappling with the...

Next Phase of Operations at GDT’s Warren Plant is Progressing

LINKEDIN POST – Green Distillation Technologies – Announcement November 2024 View Post A big thanks to Glenn and his Kitson Manufacturing Solutions team. The next phase of operations at the GDT’s Warren Plant is taking...

The GDT expansion is taking shape.

LINKEDIN POST – Green Distillation Technologies – Announcement November 2024 View Post The team at Kitson Manufacturing Solutions have delivered the important loading tubes and other pieces of the puzzle making up the soon to...

GDT ramps up tyre recycling in NSW central west.

MEDIA RELEASE – Green Distillation Technologies – Announcement02/07/2024 Green Distillation Technologies (GDT) will soon be recycling 160 tonnes (5,000 mixed tyres up to super single size) of end-of-life (EOL) tyres at its Warren facility every...

Our Work So Far...

For Investors