Tyre recycler Green Distillation Technologies, which has world-first technology that turns end of life tyres into high value oil, carbon and steel, has reasserted its commitment to build a plant in Toowoomba.

GDT’s Chief Operating Officer Trevor Bayley has said that they had expected to start construction last year after they had received approval from the Toowoomba Regional Council and a licence from the Queensland EPA, but the project has been delayed in raising the finance to fund the $12 million required to get the plant operational.

“We are still in discussion with the Queensland Government, but like most Governments around Australia, they have a lot on their plate at present.

“In February we launched a private equity fund raising for $30 million which will build Toowoomba and bring our other Australian facility at Warren in Western New South Wales to full production as well as our other international plants.

“This campaign has met with some fundraising success and we are pleased that the Motor Traders Association of Queensland has become a shareholder.

“This is a very forward thinking, responsible and community minded move by the MTAQ, as it represents some 15,500 employers in the retail, repair and service sectors of Queensland’s automotive/mobility industry, employing in excess of 90,000 people who generate more than $20 billion annually,“ he said.

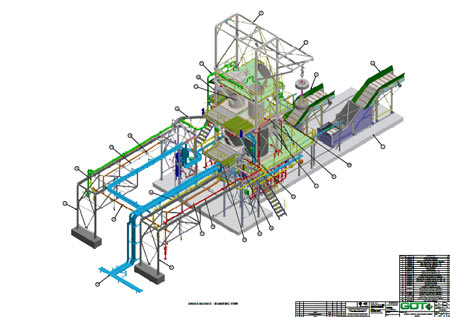

The Toowoomba GDT tyre recycling plant will be built at the Wellcamp Business Park, near the Airport and when completed will process approximately 658,000 end of life tyres per year into eight million litres of oil, 7,700 tonnes of carbon black and 2,000 tonnes of steel.

“It will employ 14 to 18 people full time, as well as local contractors during the construction phase and create further jobs in transport associated with collection of end of life tyres from retailers and other outlets,” Trevor said.

These are all valuable raw materials with the oil to go to the Southern Oil refinery at Gladstone and the carbon is a chemical building block widely used in manufacturing, while the steel beading and reinforcing of the tyre will go to be recycled into new steel

“The oil is regarded by Southern Oil as ‘light crude’ that is low in sulphur and easy to refine into petrol, diesel or jet fuel,” Trevor said.

Trevor Bayley said that GDT has a firm commitment from Southern Oil to take all the oil they produce anywhere in Australia.

“There are ample quantities of end-of-life tyres generated in the Toowoomba region with the local one million contributing to the annual 25 million in Australia each year.

“We have set an end of life tyre collection area of a three-hour truck radius from Toowoomba, which will take us to the Gold Coast, the New South Wales border, west to Chinchilla and include Brisbane, Ipswich, Roma and Kingaroy.

“We have discussed setting up a tyre collection transport service with Ability Enterprises of Toowoomba, which is a not-for-profit social enterprise business established to give people a second chance through employment and they are excited at the prospect,” he said.

He said that currently end of life tyres from the Toowoomba area are sent to Brisbane for recycling, which is mainly by cutting the tyres into pieces and sending them to landfill or grinding them into crumbs, but both methods don’t change the composition of the tyre and it will remain a tyre until eternity.

“In the case of crumbing, although some of the tyre crumb is used for sporting fields and kiddies’ playgrounds, it is really just putting off the need for recycling and as they have found in the United States the only way of disposing of end-of-life synthetic grass is by burning or landfill.

“The move by the Australian Government to ban the export of whole tyres by the end of 2021 will mean that our tyre recycling capacity will be inadequate so we need to step up our efforts.

“As well as Toowoomba and Warren, we have identified five other locations in Australia as sites for future tyre recycling, which are Gladstone, Wagga, Geelong, Elizabeth and Collie (WA). These plants would give us the capacity to recycle 30% of Australia’s end of life tyres.

“In addition, the soundness of our technology has been further vindicated with an agreement worth $50 million in South Africa, with the first in Cape Town and all the capital funding sourced locally.

“We also have an agreement in the United States In a deal worth $US150 million,” Trevor said.

Released for Green Distillation Technologies by Dennis Rutzou Public Relations (www.drpr.com.au)

For further information please call or Dennis Rutzou on 0411 10 888