High quality carbon is produced from old tyres by the world-first Australian process developed by Green Distillation Technologies that recycles end-of-life tyres.

This is in addition to the oil, which is an easy to refine crude that is used to make diesel, and could be further refined into jet fuel and the steel skeleton of the tyre, which either goes back to the tyre manufacturer for reuse or goes to scrap steel.

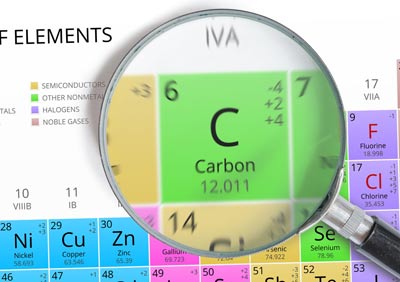

Carbon, also known as carbon black, is one of the most widely used products in manufacturing and finishes up in new tyres, printing inks, paints and coatings, plastics and cosmetics and now a new market is emerging as carbon is replacing coking coal in steel manufacturing.

Coking coal is produced via a pyrolysis process that improves the calorific value of the coal and then crushed and burnt to melt the ore. Carbon is also added to the molten iron to make steel.

But high quality carbon, such as that produced from old tyres by GDT, has higher calorific value and does not need costly pre-preparation before use and since much of the coking coal used in Australia is imported, it is therefore much cheaper to use.

This is only part of the carbon black story as the world market is expected to surpass $25 billion by 2020 and is growing at a compound annual growth rate of over 4%, which is driven by rising demand from the tyre industry, as well as the construction and manufacturing sectors which use carbon black to provide strength to industrial rubber compounds and other equipment.